AC-33 (Fused cast AZS33 block)

Category:

Fused AZS Refractory Product

Tel:

E-mail:

Introduction

The series oxidized fused cast AZS (Alumina-Zirconia-Silica) blocks are formulated with high puring raw material and manufactured by electric arc furnace and oxidized fused cast process. This fused cast process almost eliminated carbon contamination from the graphite electrodes. This process combined with superior high purity raw material contributes to high corrosion resistance of oxidized fused cast AZS (Alumina-Zirconia-Silica) blocks to molten glass, and minimal contamination to molten glass.

AC-33 (AZS 33)

The compact micro-structure of AZS-33 enables it to have very good corrosion resistance to molten glass. It very rarely results in stoning and has very limited chances to cause blistering and other defects to glass, so AZS-33 is the most common product used in the glass furnace. AZS 33 mainly used in the position of melter superstructure, work end sidewall, paving tile and channel,etc.

Typical Chemical Composition

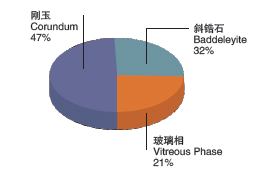

Typical Crystallographic Analysis:

Physical Properties

| Item | Typical Value | |

| True Specific Gravity | 3.84g/cm3 | |

| Apparent Porosity | 1.2% | |

| Cold Crushing Strength | 350MPa | |

| Exudation Temp | 1400℃ | |

| Static corrosion of molten glass (Soda-lime glass, 1500℃ *36 h) | 1.45mm/24h | |

| Blister rate (Soda-lime glass, 1300℃ *10 h) | 1.4% | |

| Bulk density | PT/QX | 3.45 g/cm³ 3 |

| ZWS | 3.7 g/cm³ 3 | |

| WS | 3.72 g/cm³ 3 |

Casting Technology

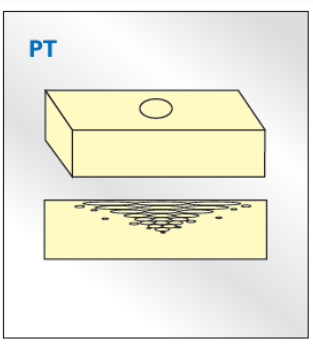

Normal Cast

Some shrinkage voids are formed under the casting scar in the annealing process.The blocks(PT)having such voids are usually installed and used in the area with no serious corrosion and the surface with scar is not used as working face,considering no influence for furnace performance and life.

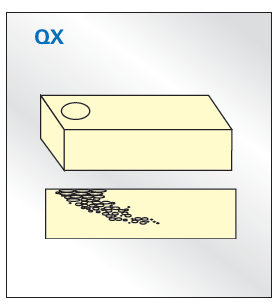

Tilting Cast

A special casting technique which causes shrinkage voids to be concentrated toward one end of the blocks,allowing the other end to become compact for maximum use.

End cast

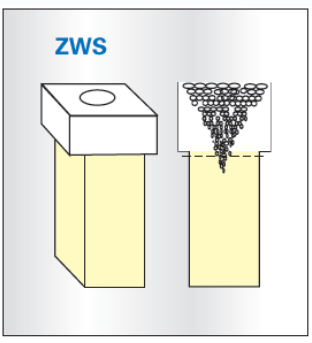

ZWS casting reserves only a few small voids under the casting scar and produces a very compact structure,so it is widely used in production of melter sidewall blocks.

Void Free Cast

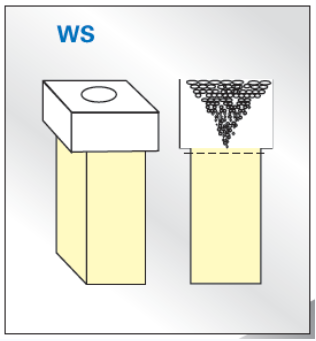

Casting is performed with a large header in which most of the voids are concentrated.The header is subsequently cut off after cooling.The resultant block is compact and substantially void-free.AC-41 and AC-M are preferably in WS casting.

Key words:

AC-33 (Fused cast AZS33 block)

Previous:

Message

Related Products