AC-DM (Fused cast mullite block)

Category:

Fused Mullite Refractory Product

Tel:

E-mail:

Introduction

AC-DM (Fused Cast Mullite block) is made of the high grade mullite grog. It mainly used in the position required good wear-resistance and high temperature resistance,such as the sliding rail brick of pusher-type reheating furnace and steel tapping spout of step-type heating furnace and garbage incinerator lining, etc.

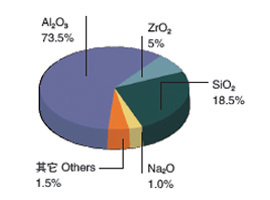

Typical Chemical Composition:

Typical Crystallographic Analysis:

Typical Physical Properties:

| Item | Value | |

| True Specific Gravity | 3.54g/cm3 | |

| Apparent Porosity | 8.0% | |

| Cold Crushing Strength | 350MPa | |

| Thermal Conductivity at 500-1500 ℃ | 4.6W/m.K | |

| Thermal Expansion at 1150℃ | 0.8% | |

| Bulk density | PT | 2.8 g/cm3 |

| WS | 3.0 g/cm3 |

Casting Technology

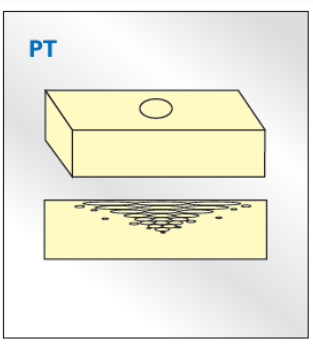

Normal Cast

Some shrinkage voids are formed under the casting scar in the annealing process.The blocks(PT)having such voids are usually installed and used in the area with no serious corrosion and the surface with scar is not used as working face,considering no influence for furnace performance and life.

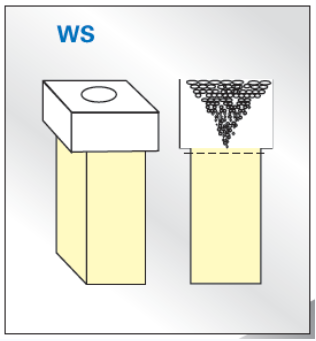

Void Free Cast

Casting is performed with a large header in which most of the voids are concentrated.The header is subsequently cut off after cooling.The resultant block is compact and substantially void-free.AC-41 and AC-M are preferably in WS casting.

Message

Related Products