AC-M (Fused cast α-β alumina block)

Category:

Fused Alumina Refractory Product

Tel:

E-mail:

Introduction

Fused Cast Alumina Refractory Block

Fused Cast Alumina Refractory Block are made from the imported high-temperature aluminum powder, that be melted in the special electric arc furnace with above 2000 degrees temperature. according to the different composition ratio of α phase corundum and β phase corundum, Fused Cast Alumina Refractory Block is divided into Fuse cast α-β alumina block, Fuse cast β alumina block and Fuse cast α alumina block.

Many years of devotion to research, development and production of fused cast alpha-beta alumina products afforded ACRC the most mature manufacturing experience and the highest technology in China. The alpha-beta alumina blocks made by ACRC were installed in many glass furnace. All the furnace's campaigning parameters reached designed requirements and world top standards of oxygen furnaces. The quality and reliability has afterwards received many more recognition following other installations in large-scale solar PV glass furnaces of high end glass companies .

AC-M (Fused Cast Α-Β Alumina Block)

AC-M (Fused Cast α-β Alumina Block)block is formed by the compact structure of α-Al2O3 and β-Al2O3 crystals in a most ideal proportion. It has good corrosion resistance and stability. Its feature is that when in contact with molten glass it barely produces any blistering. So, AC-M (Fused Cast α-β Alumina Block)blocks may be widely used in the parts such as working tank, channel and superstructures like melter crown, etc.

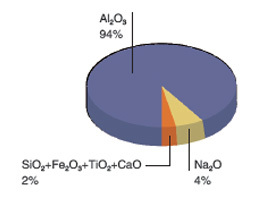

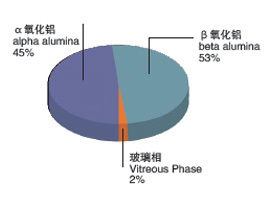

Typical Chemical Composition:

Typical Crystallographic Analysis:

Typical Physical Properties

| Item | Value | |

| True Specific Gravity | 3.54g/cm3 | |

| Apparent Porosity | 2.0% | |

| Cold Crushing Strength | 200MPa | |

| Static corrosion of molten glass (Soda-lime glass, 1350℃ *48 h): |

0.3mm/24h | |

| Bulk density | PT | 3.2 g/cm3 |

| WS | 3.4 g/cm3 |

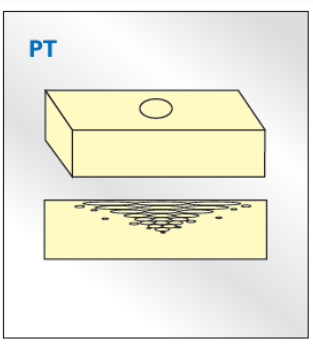

Casting Technology

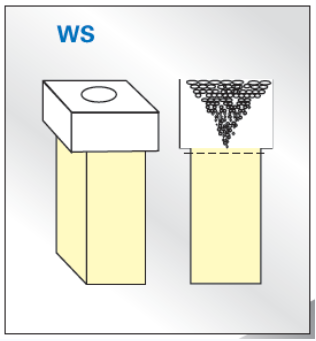

Normal Cast

Some shrinkage voids are formed under the casting scar in the annealing process.The blocks(PT)having such voids are usually installed and used in the area with no serious corrosion and the surface with scar is not used as working face,considering no influence for furnace performance and life.

Void Free Cast

Casting is performed with a large header in which most of the voids are concentrated.The header is subsequently cut off after cooling.The resultant block is compact and substantially void-free.AC-41 and AC-M are preferably in WS casting.

Key words:

AC-M (Fused cast α-β alumina block)

Previous:

Message

Related Products