AC- 41 (Fused cast AZS 41 block)

Category:

Fused AZS Refractory Product

Tel:

E-mail:

Introduction

AZS 41 has the most free baddeleyite crystals among the electro-fused Al2O3-ZrO2-SiO2 series products, which are evenly distributed within block. Its corrosion resistibility is the best and thus AZS 41 is usually recommended to be used in quick wear positions to balance the furnace life, such as sidewall of the furnace hot point, corner block, throat, weir block, bubble block and the whole electric furnace.

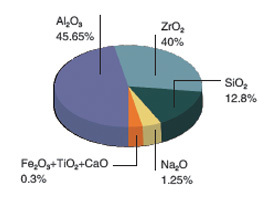

Typical Chemical Composition:

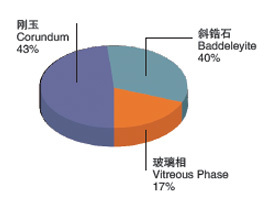

Typical Crystallographic Analysis:

Typical Physical Properties:

| Item | Value | |

| True Specific Gravity | 4.1g/cm3 | |

| Apparent Porosity | 1.0% | |

| Cold Crushing Strength | 350MPa | |

| Exudation Temp. | 1400 ℃ | |

| Static corrosion of molten glass (Soda-lime glass, 1500℃ *36 h): |

1.2mm/24h | |

| Blister rate (Soda-lime glass, 1300℃ *10 h): |

1.0% | |

| Bulk density | ||

| ZWS | 3.9 g/cm3 | |

| WS | 3.95 g/cm3 |

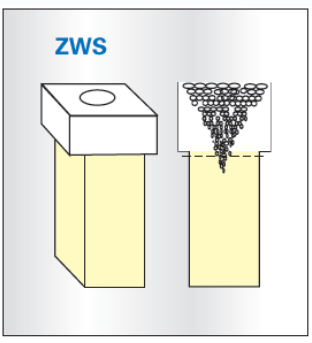

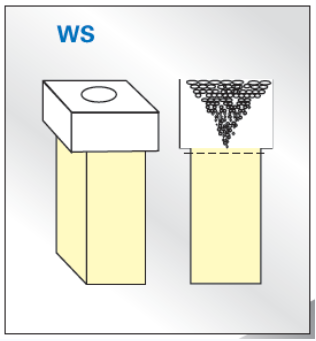

Casting Technology

End cast

ZWS casting reserves only a few small voids under the casting scar and produces a very compact structure,so it is widely used in production of melter sidewall blocks.

Void Free Cast

Casting is performed with a large header in which most of the voids are concentrated.The header is subsequently cut off after cooling.The resultant block is compact and substantially void-free.AC-41 and AC-M are preferably in WS casting.

Key words:

AC- 41 (Fused cast AZS 41 block)

Next:

Message

Related Products