AC- 36S (Fused cast AZS36S block with Low Silicon Low Sodium)

Category:

Fused AZS Refractory Product

Tel:

E-mail:

Introduction

With lower SiO2 and Na2O content, AC-36S bears less vitreous phase, higher exudation temperature, better high-temperature stability and superior corrosion resistance to molten glass, and thusly is the most ideal material to realize glass furnace’s overall insulation, energy-efficiency and longevity.

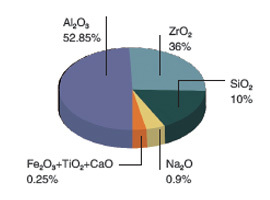

Typical Chemical Composition:

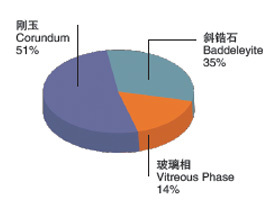

Typical Crystallographic Analysis:

Typical Physical Properties:

| Item | Value | |

| True Specific Gravity | 3.95g/cm3 | |

| Apparent Porosity | 1.0% | |

| Cold Crushing Strength | 350MPa | |

| Exudation Temp. | 1400 ℃ | |

| Static corrosion of molten glass (Soda-lime glass, 1500℃ *36 h): |

1.4mm/24h | |

| (Soda-lime glass, 1300℃ *10 h): | 1.2% | |

| Bulk density | ||

| WS | 3.8 g/cm3 |

Casting Technology

Void Free Cast

Casting is performed with a large header in which most of the voids are concentrated.The header is subsequently cut off after cooling.The resultant block is compact and substantially void-free.AC-41 and AC-M are preferably in WS casting.

Key words:

AC- 36S (Fused cast AZS36S block with Low Silicon Low Sodium)

Previous:

Message

Related Products